Exertherm is ideal for companies that need full monitoring of critical electrical circuits than monitoring one time over several periods. By this method, the chances of detecting damage to electrical equipment will be much better ( predict 70% more failures ). Sensors are permanently installed in energized electrical equipment to directly view and continuously monitor the condition of critical joints. This can also reduce the risk of work accidents that can occur on damaged equipment when monitoring is carried out manually.

What is the benefits :

- Increased operator & facility safety

- Increased operational uptime

- Reduced risk of fire/explosion resulting from Arc Flash

- Real-time data = improved critical asset integrity

- Reduced unplanned maintenance

- OEM vendor neutral

- Suitable for retrofit or new-build

- Enhanced protection for critical circuits operating at low load

How this can works?

“source : exertherm.com”

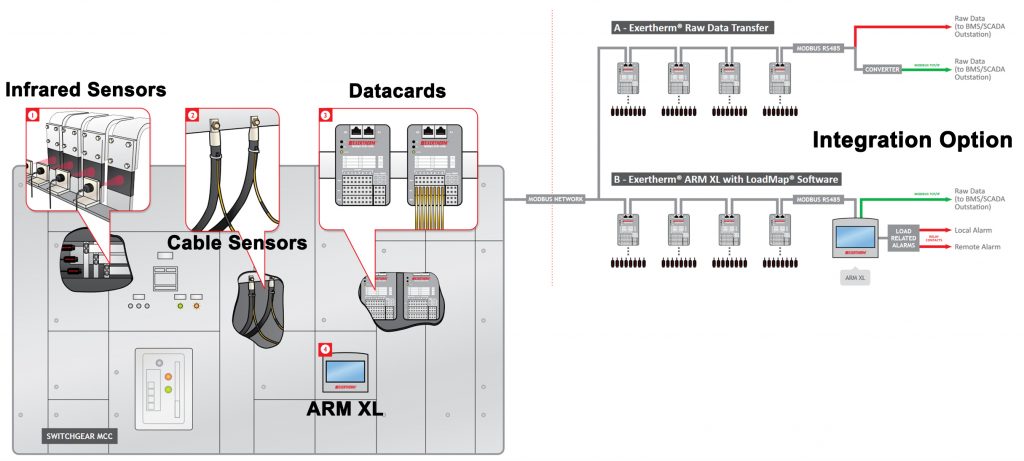

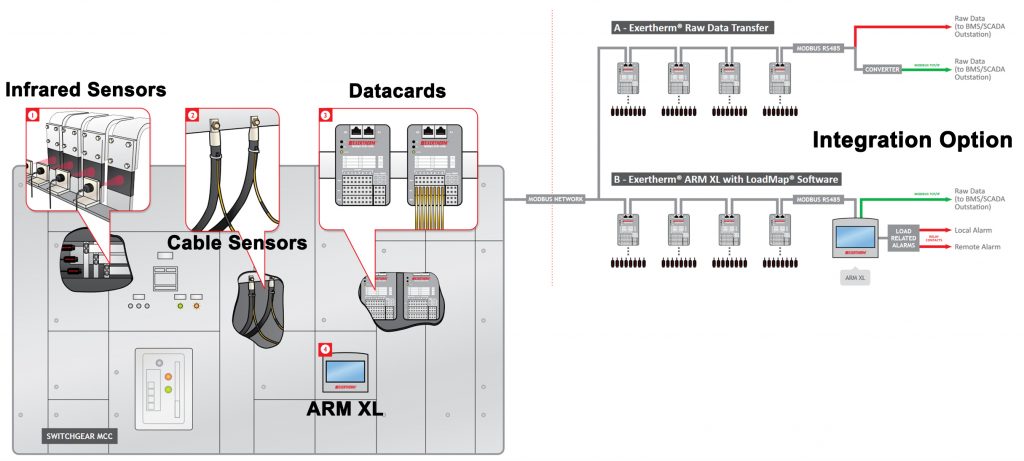

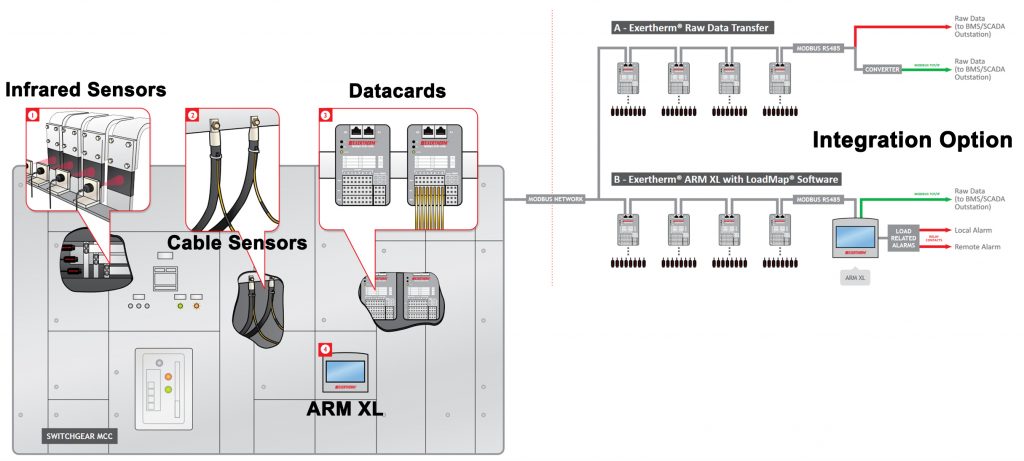

Infrared Sensors

Sensors are placed in the enclosure to directly monitor key connections through ΔT measurement.

Cable Sensors

Exertherm’s patented cable sensors strap to the cable monitors to monitor cable joints through ΔT measurement.

Datacards

Our Datacards facilitate the collection of data from the IR or Cable sensors (8 per data card) and transmit it to the host system via the ModBus protocol.

ARM XL

They feature RJ45 sockets for easy integration and connection to your RS485 Modbus network.

Where need to monitor?

The Exertherm is fit for Low Voltage and Medium Voltage applications, the following critical

and key connections (including insulated bus) need to monitor :

- All AIS circuit breakers, line/load side

- Bus couplers, line/load side

- Critical vertical to horizontal bus connections

- MCC clamp connections

- Critical cable connections, typically above 400A (via specialist Exertherm Cable Sensors)

- All shipping/transport joints Exertherm cable sensors