Thermographic analysis provides a high-resolution, non-contact means of monitoring the condition of electrical and electromechanical equipment, roofing and wall insulation, and refractories with a detailed report is submitted including electrical anomalies found with colour photo documentation, infrared images, summaries of problems and corrective actions to be taken.

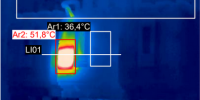

Electrical Infrared Survey

Infrared Inspection is a vital tool for identifying electrical faults by measuring temperature through analysis of infrared radiations and fire hazard can be reduced.

Mechanical Infrared Survey

Problems identified using this technology include inadequate bearing lubrication or bearing wear, inadequate coupling lubrication or wear, leaking valves or seals, and motor stator heat source emissions, indicative of possible stator problems, etc.

Gas-Leak Survey

Thermography allows us to scan large areas of insulated pipelines quickly and safely whilst identifying areas where the integrity of the insulation has become subject to water ingress. CUI – Corrosion Under Insulation is the one of the greatest concerns in the oil, gas, and petrochemical industries where highly dangerous liquids and gases are processed throughout plant pipelines.

Corrosion Infrared Survey

ThermaCAM GasFindIR camera easily locates Hydrocarbon leaks and with exact leak source info, repairs are less time consuming and less expensive. It is also cost-effectively as numerous components are scanned simultaneously, identifying gas leak with pinpoint accuracy.

The Benefit of using Infrared Thermography :

- Improved Safety ( Reduce Emergency Service call, Identify the fire hazard, Save the environment ).

- Save Money ( Prevent Equipment Failure, Save of Insurance, Reduce Downtime ).

- Save Time ( Plan and Schedule repair, Identify and prioritize areas requiring Predictive Maintenance ).

Acquisition of a systematic and pragmatic approach to the Condition-Based Maintenance Program Implemantion of the Infrared Thermography by Cistech, hope that our customers would have a proper methodology and approach to a successful Condition-Based Maintenance Program especially when using the Calibrated and Certified Professional Camera from FLIR Thermogaphy thermal and supported by Level 1 & 2 Certified Thermographer with an experienced in Industrial, Power Plant and Oil & Gas Companies.

About Us

PT. Cistech Alpha Indonesia is an Engineering Company focuses in providing high quality products and services in the area of preventive and predictive maintenance.

Reach Us

Contact Us

Monday – Friday : 08.30 AM to 05.00 PM

Saturday : Closed

Phone : +62 (21) 22522445

Email : info@ptcai.com

Address : Green Sedayu Biz Park Blok DM-6 No.15,

Jl. Daan Mogot Raya Km.18, Kalideres,

West Jakarta – 11840